Understanding the Strength, Safety, and Value of Fiberglass Grating

Different Types of Fiberglass Grating and Their Applications

Fiberglass grating is a versatile material that finds its use in a variety of applications due to its exceptional properties. Primarily, fiberglass grating is categorized into three main types: molded, pultruded, and phenolic grating. Each type offers distinct advantages that make them suitable for specific uses.

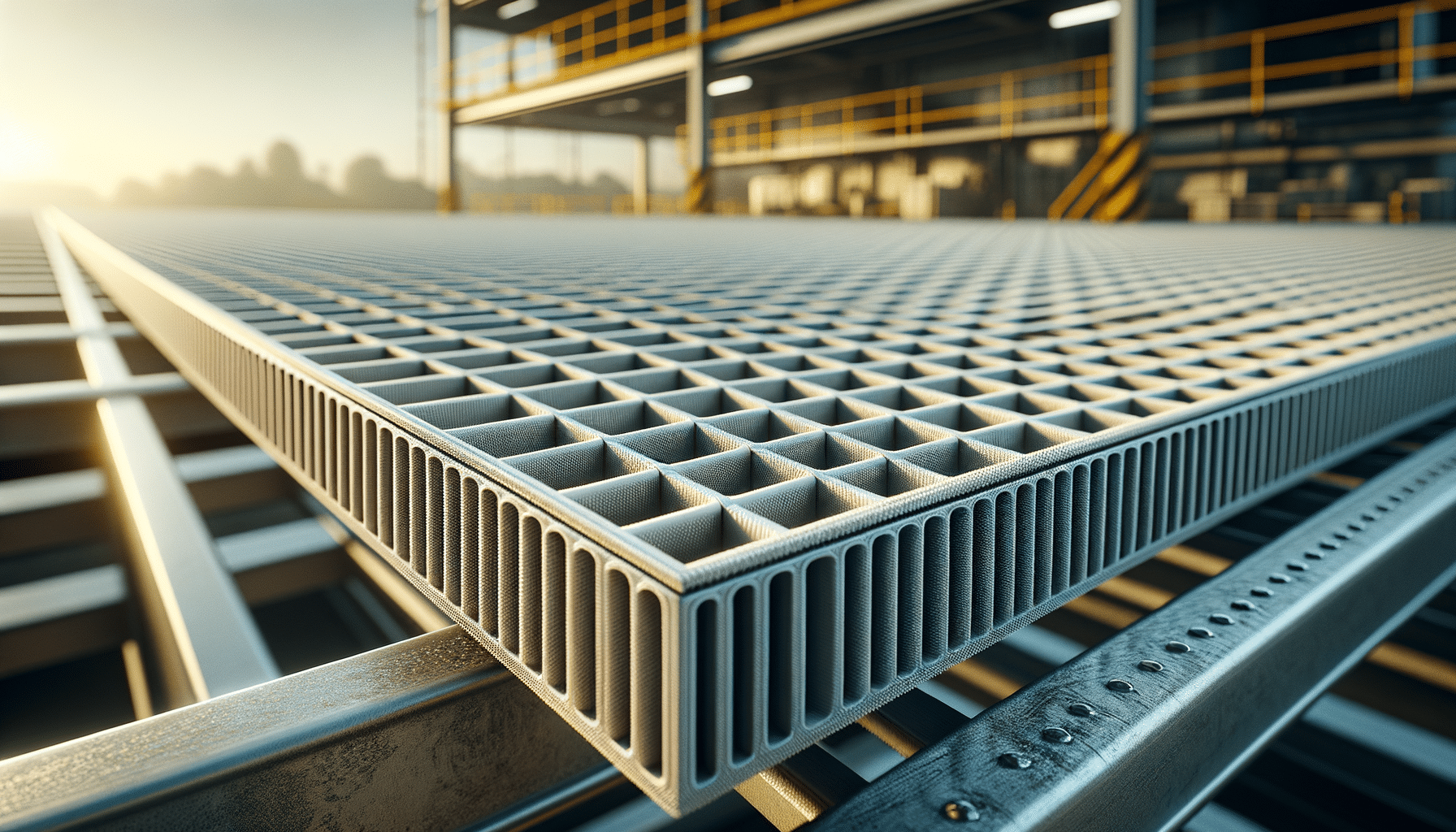

Molded fiberglass grating is produced by a process of interweaving continuous glass fibers and resin into a mold. This type is ideal for applications requiring corrosion resistance and high strength-to-weight ratio, such as in chemical plants and marine environments. Its non-slip surface makes it a preferred choice for walkways and platforms where safety is paramount.

On the other hand, pultruded fiberglass grating is made by pulling continuous fiberglass strands through a resin bath and a heated die. This results in a product with a higher glass content, giving it superior load-bearing capacity. Pultruded grating is well-suited for industrial flooring applications where heavy loads are common, such as in factories and warehouses.

Phenolic grating, a relatively newer innovation, is crafted using phenolic resin. It offers enhanced fire resistance and low smoke emissions, making it ideal for offshore and transportation industries where these characteristics are crucial. Its ability to withstand extreme temperatures without degrading further expands its application in challenging environments.

Understanding the different types of fiberglass grating and their applications helps in selecting the right product for specific needs. The choice depends on factors such as environmental conditions, load requirements, and safety considerations, ensuring both functionality and longevity.

Key Features to Consider When Choosing Fiberglass Grating

When selecting fiberglass grating for your project, several key features should be taken into account to ensure you make a well-informed decision. These features not only affect the performance and durability of the grating but also contribute to the overall safety and cost-effectiveness of the installation.

Firstly, consider the load-bearing capacity of the grating. Depending on the intended use, you might require grating that can support significant weight. Pultruded grating typically offers higher load capacity, making it suitable for industrial settings. Conversely, if the application is less demanding, molded grating could be a more economical choice.

Corrosion resistance is another critical factor, especially in environments exposed to harsh chemicals or salty air. Molded grating excels in this aspect due to its high resin content, which provides superior resistance to corrosive substances, ensuring a longer lifespan.

Fire resistance is a vital consideration, particularly in industries where safety regulations are stringent. Phenolic grating offers exceptional fire resistance and low smoke emissions, making it a safer option for environments where fire hazards are a concern.

Additionally, consider the ease of installation and maintenance. Lightweight grating is easier to handle and install, reducing labor costs. Fiberglass grating is generally low maintenance, but choosing a type with a non-slip surface can further enhance safety and reduce the risk of accidents.

By evaluating these key features, you can choose fiberglass grating that meets your specific needs, ensuring optimal performance, safety, and value for your investment.

Pricing Insights, Maintenance Tips, and Long-Term Value of Fiberglass Grating

Investing in fiberglass grating involves understanding its pricing dynamics, maintenance requirements, and the long-term value it offers. While initial costs can vary based on the type and specifications, fiberglass grating is often more cost-effective in the long run compared to traditional materials.

The price of fiberglass grating depends on factors such as the type (molded, pultruded, or phenolic), size, thickness, and any additional features like fire retardancy or custom colors. Generally, molded grating tends to be more affordable than pultruded or phenolic options due to its simpler manufacturing process. However, the choice should be guided by the specific needs of the project rather than just cost.

Fiberglass grating is renowned for its low maintenance requirements. Regular cleaning with mild detergent and water is usually sufficient to keep it in good condition. Inspecting the grating periodically for any signs of wear or damage is advisable, particularly in high-traffic areas, to ensure continued safety and performance.

In terms of long-term value, fiberglass grating offers significant advantages. Its durability and resistance to corrosion and environmental factors mean fewer replacements and repairs, translating to cost savings over time. Additionally, its inherent safety features, such as non-slip surfaces and fire resistance, contribute to a safer working environment, potentially lowering insurance costs and liability risks.

Overall, while the initial investment in fiberglass grating might be higher compared to some alternatives, its long-term benefits make it a wise choice for applications requiring reliability, safety, and minimal maintenance.

Conclusion: The Strength and Safety of Fiberglass Grating

Fiberglass grating stands out as a robust and versatile solution for a wide range of industrial and commercial applications. Its variety of types—molded, pultruded, and phenolic—each offers unique benefits that cater to specific needs, whether it is enhanced load capacity, corrosion resistance, or fire safety.

By carefully considering key features such as load capacity, corrosion and fire resistance, and ease of installation, you can select the most suitable fiberglass grating for your project. This ensures not only optimal performance and safety but also cost-effectiveness in the long run.

Understanding the pricing dynamics and maintenance tips further enhances the decision-making process, providing insight into the long-term value that fiberglass grating offers. Its durability and low maintenance requirements make it a compelling choice for those seeking a reliable, safe, and economical solution.

Ultimately, fiberglass grating’s strength, safety, and value make it an outstanding option for industries looking to enhance their infrastructure while maintaining high standards of safety and efficiency.