Understanding Laser Welding Technology in Modern Manufacturing

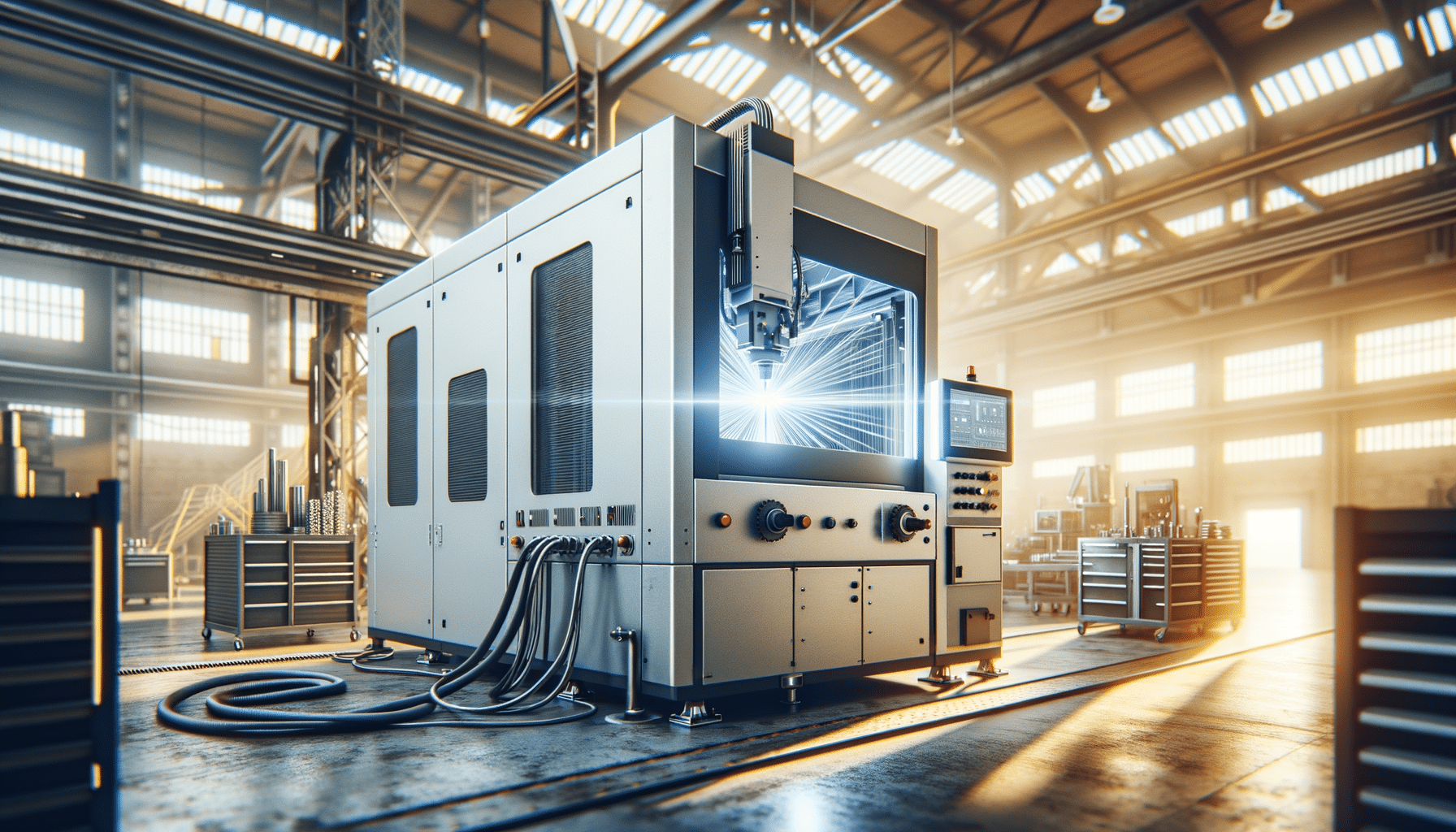

Introduction to Laser Welding Technology

Laser welding technology has emerged as a transformative force in modern manufacturing. This advanced technique uses concentrated laser beams to join materials, offering unparalleled precision and efficiency. Unlike traditional welding methods, laser welding minimizes thermal distortion and allows for intricate designs and complex geometries. This makes it particularly valuable in industries like automotive, electronics, and aerospace, where precision is paramount.

The significance of laser welding lies in its ability to create high-quality welds with minimal human intervention. The process is highly automated, reducing labor costs and increasing productivity. Furthermore, laser welding is environmentally friendly, producing fewer emissions and waste compared to conventional welding methods. As manufacturing industries continue to evolve, the adoption of laser welding technology is expected to rise, driven by its numerous advantages.

Types of Laser Welding Machines

Laser welding machines come in various types, each designed for specific applications and materials. Understanding these types is crucial for selecting the right machine for a particular manufacturing process.

One common type is the fiber laser welding machine, known for its high power efficiency and excellent beam quality. These machines are ideal for welding reflective metals like aluminum and copper. Another type is the CO2 laser welding machine, which is suitable for non-metal materials such as plastics and ceramics. CO2 lasers are often used in industries where non-metal welding is required.

The solid-state laser welding machine is another option, utilizing crystals like Nd:YAG to generate powerful beams. These machines are versatile and can weld a wide range of materials, making them popular in diverse industries. Lastly, diode laser welding machines offer compactness and efficiency, often used for applications requiring low power and high precision.

Each type of laser welding machine has its unique advantages, and the choice depends on factors like material type, desired weld quality, and production volume.

Advantages of Laser Welding in Manufacturing

Laser welding offers several advantages that make it a preferred choice in various manufacturing sectors. One of the most notable benefits is its ability to produce high-quality, precise welds. This precision is crucial in industries like aerospace and electronics, where even minor defects can lead to significant issues.

Another advantage is the speed of the process. Laser welding is significantly faster than traditional methods, reducing production time and increasing throughput. This efficiency leads to cost savings, which is a critical factor for manufacturers looking to optimize operations.

Additionally, laser welding is a non-contact process, meaning it does not require physical contact with the materials being welded. This reduces wear and tear on the equipment and minimizes the risk of contamination. The process also generates minimal heat-affected zones, preserving the integrity of the materials and reducing the need for post-weld treatments.

- High precision and quality welds

- Increased production speed and efficiency

- Minimal heat-affected zones

- Reduced contamination risk

These advantages underscore the growing importance of laser welding in modern manufacturing.

Factors Influencing the Prices of Laser Welding Machines

The cost of laser welding machines can vary significantly based on several factors. Understanding these factors is essential for businesses looking to invest in this technology.

One primary factor is the type of laser used in the machine. Fiber lasers, known for their efficiency and quality, tend to be more expensive than CO2 or diode lasers. The power output of the machine also influences the price. Higher power machines can handle thicker materials and more demanding applications, but they come with a higher price tag.

The brand and reputation of the manufacturer can also affect the cost. Machines from well-regarded manufacturers often come with a premium price due to their reliability and after-sales support. Additionally, features like automation capabilities, ease of integration into existing systems, and user-friendly interfaces can add to the cost.

Finally, the size and complexity of the machine play a role in determining the price. Larger, more complex machines with advanced features will typically be more expensive than smaller, simpler models.

- Type of laser

- Power output

- Manufacturer reputation

- Automation and features

- Size and complexity

By understanding these factors, businesses can make informed decisions when purchasing laser welding machines.

Conclusion: The Future of Laser Welding

As industries continue to innovate and demand higher precision and efficiency, laser welding technology is set to play an increasingly vital role. Its ability to deliver high-quality welds with minimal environmental impact makes it an attractive option for manufacturers worldwide.

The future of laser welding looks promising, with ongoing advancements in laser technology expected to further enhance its capabilities. As more industries recognize the benefits of laser welding, its adoption is likely to expand, driving further innovation and development in this field.

For manufacturers looking to stay competitive, investing in laser welding technology could be a strategic move. By understanding the types, advantages, and cost factors of laser welding machines, businesses can position themselves at the forefront of modern manufacturing.