Guide to Choosing Affordable Laser Welding Machines

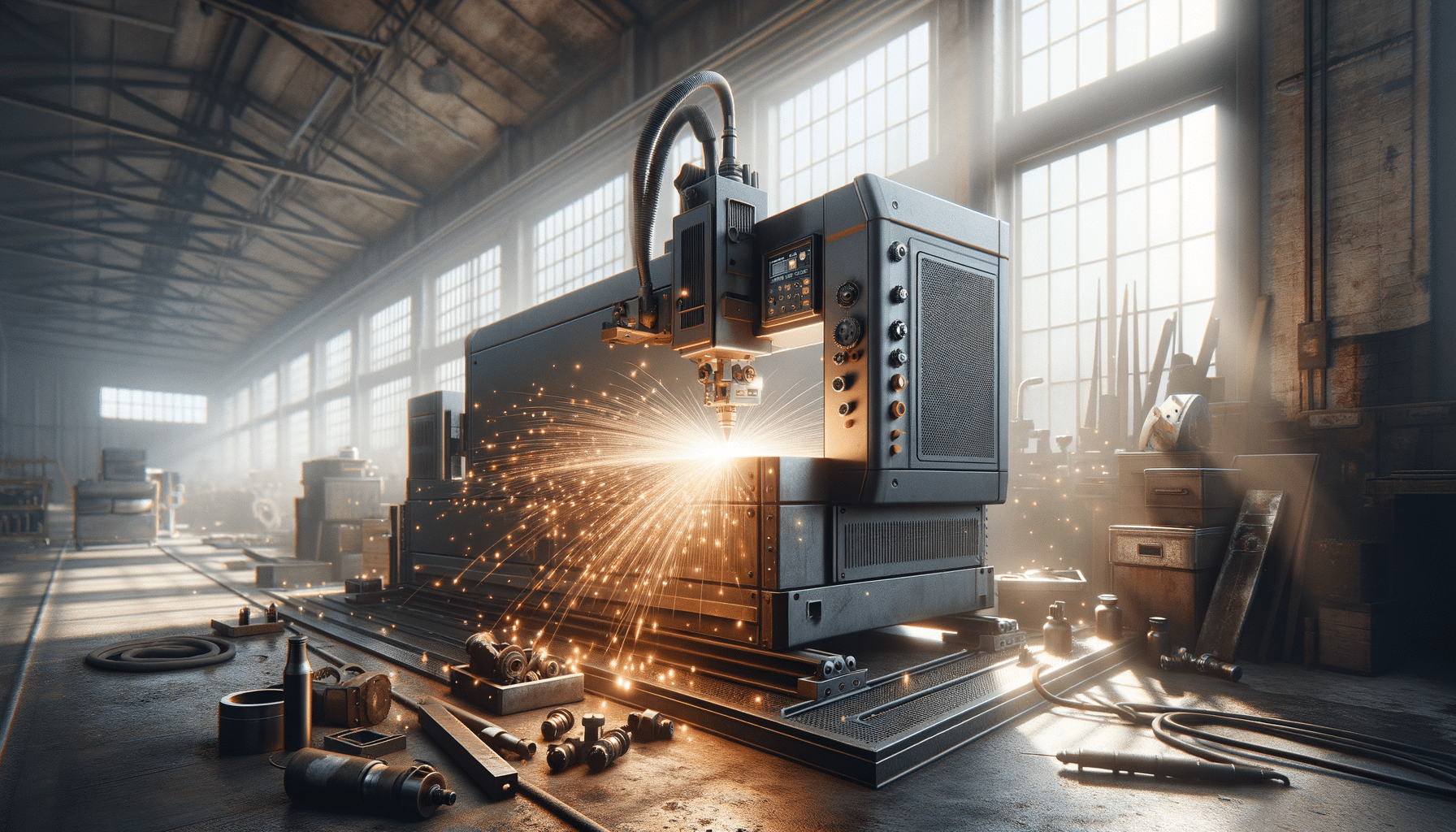

Understanding Laser Welding Machines

Laser welding machines have revolutionized the way industries approach intricate welding tasks. These machines utilize focused laser beams to join materials with precision and minimal distortion. The laser’s ability to concentrate energy into a small area allows for high-quality welds that are both robust and aesthetically pleasing.

Laser welding is particularly valued in sectors like automotive and aerospace, where precision is paramount. In the medical industry, these machines help create delicate instruments and implants, ensuring safety and reliability. Meanwhile, in jewelry making, laser welding offers artisans the ability to repair and create intricate designs without damaging precious materials.

Understanding the basic operation of laser welding machines can help potential buyers make informed decisions. The machines typically consist of a laser source, a focusing lens, and a workpiece handling system. The laser source can vary from CO2 lasers to fiber lasers, each offering distinct advantages depending on the application.

Key Features to Consider

When selecting a laser welding machine, several key features should be considered to ensure it meets the specific needs of your application. One of the primary factors is the type of laser source. Fiber lasers are known for their efficiency and ability to handle various materials, while CO2 lasers are often preferred for non-metal applications.

Another critical feature is the machine’s power output, which determines the thickness of the materials it can weld. Higher power outputs allow for welding thicker materials but may come at a higher cost. It’s essential to balance the machine’s capabilities with your budget and intended use.

Additionally, consider the machine’s operational flexibility. Some models offer adjustable settings that can be tailored to different tasks, enhancing their versatility. The ease of use and availability of support and training should also be factored in, especially for businesses new to laser welding technology.

Advantages of Laser Welding Machines

Laser welding machines offer numerous advantages over traditional welding methods. One of the most significant benefits is the precision they provide. The focused laser beam allows for small, precise welds, reducing the heat-affected zone and minimizing the risk of distortion.

Moreover, laser welding machines are known for their speed and efficiency. They can perform welds quickly, increasing productivity and reducing operational costs. This efficiency is particularly beneficial in high-volume manufacturing settings where time is of the essence.

Another advantage is the ability to weld a wide range of materials, from metals to plastics. This versatility makes laser welding a preferred choice in diverse industries, enhancing its appeal to businesses looking to streamline their welding operations.

Applications Across Industries

Laser welding machines are used in a variety of industries due to their adaptability and precision. In the automotive industry, they are employed to create strong, lightweight components that improve vehicle performance and fuel efficiency.

In the aerospace sector, laser welding is crucial for manufacturing components that withstand extreme conditions while maintaining structural integrity. The ability to produce clean, smooth welds ensures the safety and reliability of aerospace parts.

In the medical field, laser welding machines enable the production of intricate devices and implants, ensuring high standards of hygiene and precision. Their use in jewelry making also highlights their ability to handle delicate and valuable materials with care and accuracy.

Choosing the Right Machine for Your Needs

When choosing a laser welding machine, it’s essential to assess your specific needs and budget. Consider the materials you’ll be working with and the desired weld quality. Research different models and brands, taking note of customer reviews and industry recommendations.

Evaluate the machine’s compatibility with your existing equipment and processes. It’s also wise to consider future needs, ensuring the machine can adapt to evolving demands. Consulting with industry experts and suppliers can provide valuable insights and guidance.

Ultimately, selecting a laser welding machine involves balancing cost, performance, and support. By carefully considering these factors, you can invest in a machine that enhances your operations and delivers long-term value.