Affordable DTF Printers: Ideal for Startups and Small Businesses

Introduction to DTF Printing Technology

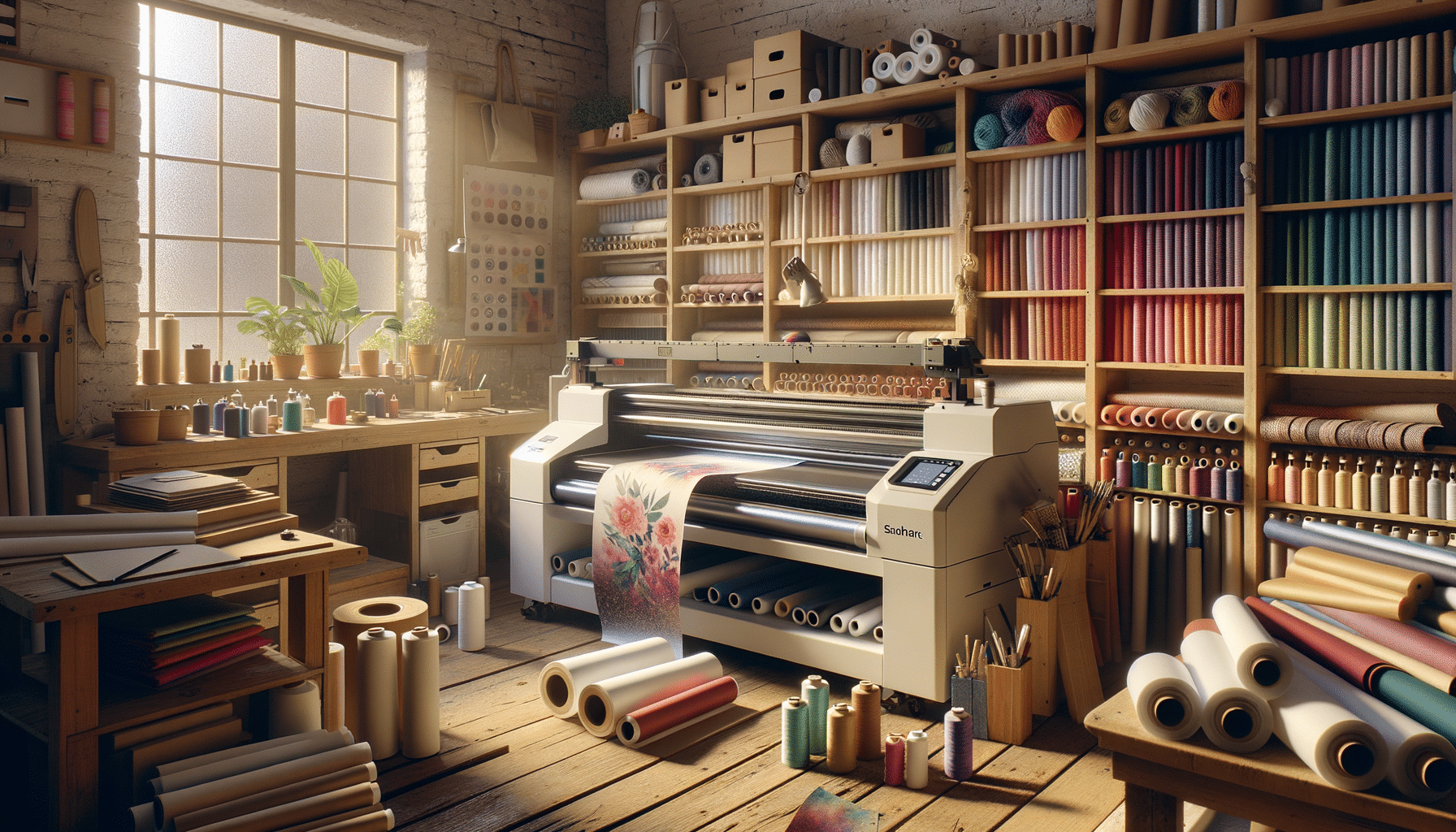

Direct-to-Film (DTF) printing has emerged as a versatile and efficient method for transferring designs onto textiles. Unlike traditional screen printing or Direct-to-Garment (DTG) methods, DTF offers a unique approach that is both cost-effective and adaptable. This technology uses a specialized film to transfer prints onto fabrics, making it a perfect choice for businesses looking to produce custom apparel with precision and vibrancy.

The popularity of DTF printing has surged due to its ability to handle complex designs and a variety of fabric types. This flexibility allows small businesses and startups to expand their product offerings without investing in multiple printing technologies. The process involves printing a design onto a film, applying a powder adhesive, and then transferring the design onto the garment using a heat press. The result is a durable, high-quality print that is resistant to fading and cracking.

For entrepreneurs and small business owners, DTF printers represent an opportunity to enter the custom apparel market with relatively low overhead. The initial investment is manageable, and the return potential is significant, given the growing demand for personalized clothing items.

Advantages of Using DTF Printers

DTF printers offer several advantages that make them a preferred choice for many businesses. One of the key benefits is their ability to print on a wide range of materials, including cotton, polyester, and blends. This versatility ensures that businesses can cater to diverse customer preferences and needs.

Another significant advantage is the vibrant and detailed prints that DTF technology can produce. The colors are rich and well-defined, making designs stand out on any garment. Additionally, the prints are highly durable, maintaining their quality even after multiple washes. This reliability is crucial for customer satisfaction and brand reputation.

Moreover, DTF printers are known for their efficiency. The process is relatively quick, allowing businesses to fulfill orders promptly without sacrificing quality. This speed is particularly beneficial for startups and small businesses that need to maintain a competitive edge in the market.

- Ability to print on various fabric types

- Vibrant and durable prints

- Efficient production process

Cost Considerations for Startups and Small Businesses

For startups and small businesses, the cost of acquiring and operating a DTF printer is a crucial factor. Fortunately, DTF printers are generally more affordable than other printing technologies, such as DTG or screen printing setups. This affordability makes them an accessible option for new businesses entering the custom apparel market.

In terms of operational costs, DTF printers require consumables like inks, films, and adhesive powders. These materials are relatively inexpensive and widely available, allowing businesses to manage their expenses effectively. Additionally, the maintenance costs for DTF printers are minimal, further enhancing their appeal to small business owners.

When considering a DTF printer, it’s essential to evaluate the potential return on investment. With the growing demand for personalized apparel, businesses can quickly recoup their initial investment by offering unique and high-quality products that attract a dedicated customer base.

Comparing DTF with Other Printing Methods

In the world of custom apparel printing, several methods are available, each with its own set of advantages and limitations. DTF printing stands out due to its unique combination of versatility, quality, and cost-effectiveness.

Compared to screen printing, DTF offers more flexibility in terms of design complexity and fabric compatibility. While screen printing is suitable for large batches with simple designs, DTF excels in producing detailed and colorful prints on a variety of materials. This capability makes it ideal for businesses that cater to niche markets or produce limited edition runs.

When compared to DTG printing, DTF is often more cost-effective, particularly for small to medium-sized orders. DTG requires pretreatment of garments and is generally limited to cotton fabrics, whereas DTF can be applied to a broader range of materials without additional preparation. This flexibility allows businesses to diversify their product offerings without additional costs.

- Flexibility in design and material compatibility

- Cost-effective for small to medium orders

- Less preparation required compared to DTG

The Future of DTF Printing in the Market

As the demand for personalized and custom apparel continues to grow, the role of DTF printers in the market is becoming increasingly significant. The technology is constantly evolving, with improvements in print quality, speed, and efficiency making it even more attractive to businesses of all sizes.

Innovations in DTF printing are likely to focus on enhancing the sustainability of the process. This includes developing eco-friendly inks and adhesives that reduce environmental impact while maintaining print quality. Additionally, advances in automation could further streamline the printing process, allowing businesses to increase their output without additional labor costs.

For startups and small businesses, staying ahead of trends in DTF printing can provide a competitive advantage. By investing in this technology and keeping an eye on industry developments, these businesses can offer cutting-edge products that meet the evolving needs of their customers. As such, DTF printing is poised to remain a crucial component of the custom apparel industry for years to come.