How DTF Printing Technology is Changing Textile Decoration

Introduction to DTF Printing Technology

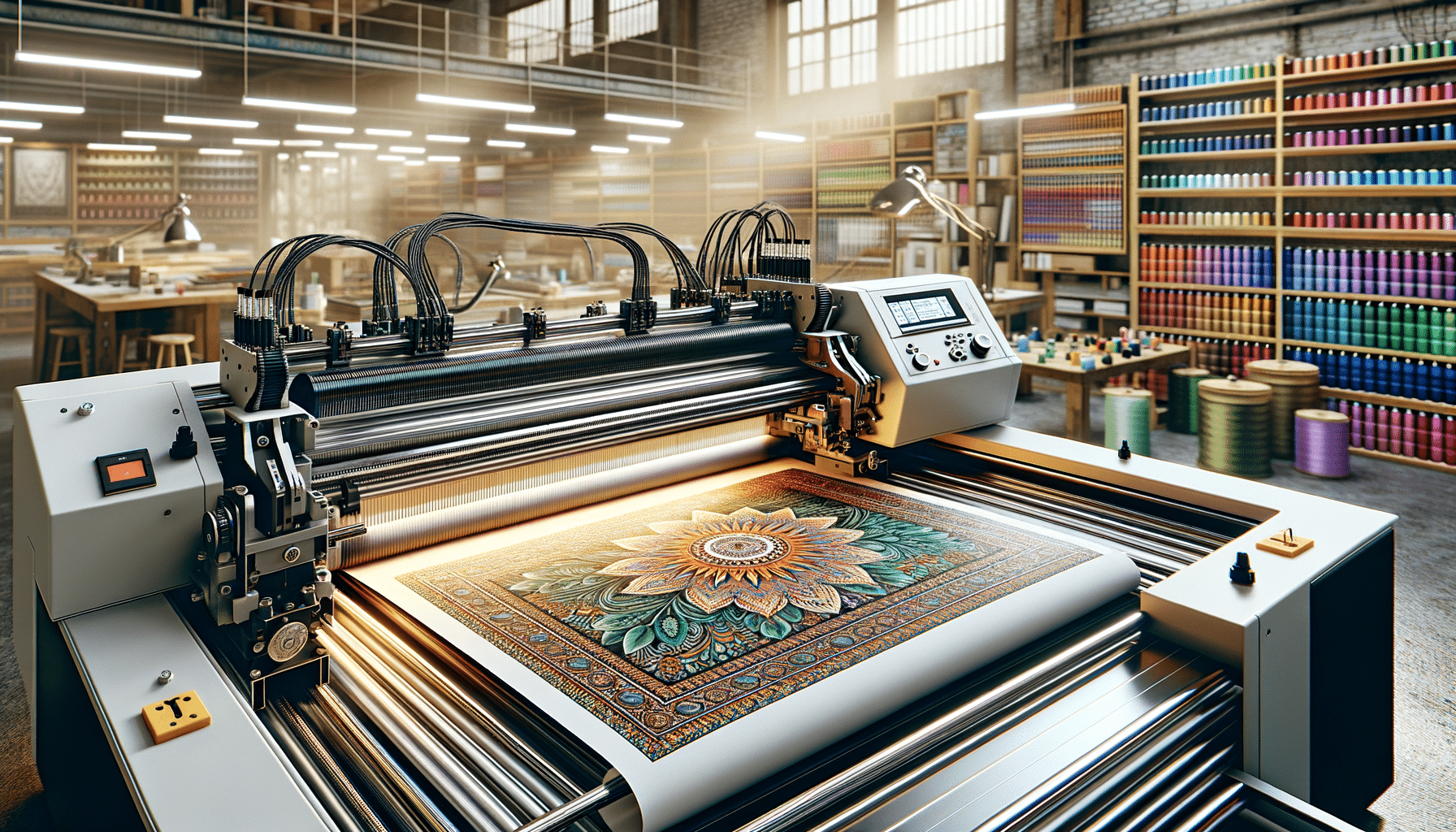

Direct-to-film (DTF) printing is revolutionizing the textile decoration industry with its innovative approach. Unlike traditional methods, DTF printing allows for a seamless transfer of designs onto various fabrics without the need for pre-treatment or complex setups. This technology is gaining popularity due to its ability to produce vibrant and durable prints that adhere well to different types of textiles. As the demand for personalized and unique garments increases, DTF printing offers a flexible solution that meets these needs efficiently.

DTF printing works by printing designs onto a special film, which is then heat-pressed onto the fabric. This process allows for intricate details and a wide range of colors, making it suitable for both simple and complex designs. Industries such as fashion, sportswear, and customized apparel are adopting DTF technology to enhance their product offerings and meet consumer expectations.

The Advantages of DTF Printing in Textile Decoration

One of the main advantages of DTF printing is its versatility. It can be used on a variety of fabrics, including cotton, polyester, and blends, making it a preferred choice for businesses looking to diversify their product lines. The technology’s ability to produce high-quality prints with minimal setup time is another significant benefit, allowing for faster production cycles and reduced costs.

DTF printing is also known for its durability. The prints are resistant to washing and wear, maintaining their vibrancy over time. This feature is particularly appealing to consumers who value longevity in their clothing items. Additionally, DTF technology supports eco-friendly practices, as it requires less water and energy compared to traditional printing methods.

Moreover, DTF printing allows for creative freedom. Designers can experiment with different textures and effects, creating unique products that stand out in the market. This capability is crucial in an industry where innovation and differentiation are key to success.

Indicative Prices of DTF Printers

The cost of DTF printers varies depending on the model and features. Entry-level printers, suitable for small businesses or startups, can range from a few thousand dollars. These models offer essential functionalities but may have limitations in terms of speed and size.

Mid-range DTF printers, which provide a balance between cost and capability, are priced between five to ten thousand dollars. They are ideal for medium-sized businesses that require higher production volumes and additional features such as automated functions and advanced color management.

High-end DTF printers, designed for large-scale operations, can exceed ten thousand dollars. These models offer the latest technology, ensuring exceptional print quality and efficiency. Businesses investing in these printers often do so to meet high demands and maintain a competitive edge in the market.

When considering a DTF printer, it’s essential to evaluate the specific needs of your business, including production capacity and budget constraints. Investing in the right printer can significantly impact your operations and profitability.

Applications of DTF Printing Across Various Industries

DTF printing is not limited to clothing and fashion. Its applications extend to various industries, offering innovative solutions for textile decoration. In the sportswear industry, DTF technology is used to create custom jerseys and team apparel that require durability and flexibility.

The promotional products industry also benefits from DTF printing, as it allows for the creation of customized items such as tote bags, caps, and other merchandise. The ability to print on different materials opens up endless possibilities for branding and marketing initiatives.

Home décor is another area where DTF printing is making an impact. From personalized pillowcases to decorative wall hangings, the technology enables consumers to express their creativity and personalize their living spaces.

Furthermore, DTF printing is gaining traction in the art and design community. Artists can experiment with fabric printing, creating unique pieces that combine traditional art techniques with modern technology. This fusion of art and textile offers new avenues for artistic expression and commercial opportunities.

Conclusion: The Future of DTF Printing in Textile Decoration

The future of DTF printing in textile decoration looks promising. As technology continues to evolve, we can expect further advancements that will enhance the capabilities and applications of DTF printing. Businesses that embrace this technology now will be well-positioned to capitalize on emerging trends and consumer preferences.

DTF printing offers a sustainable and efficient solution for textile decoration, meeting the demands of a dynamic and competitive market. Its versatility, quality, and cost-effectiveness make it an attractive option for businesses of all sizes.

As the industry continues to grow, staying informed about the latest developments in DTF printing will be crucial for those looking to maintain a competitive edge. By leveraging the benefits of this technology, businesses can offer innovative products that resonate with consumers and drive growth.