Guide to Choosing Affordable Laser Welding Machines

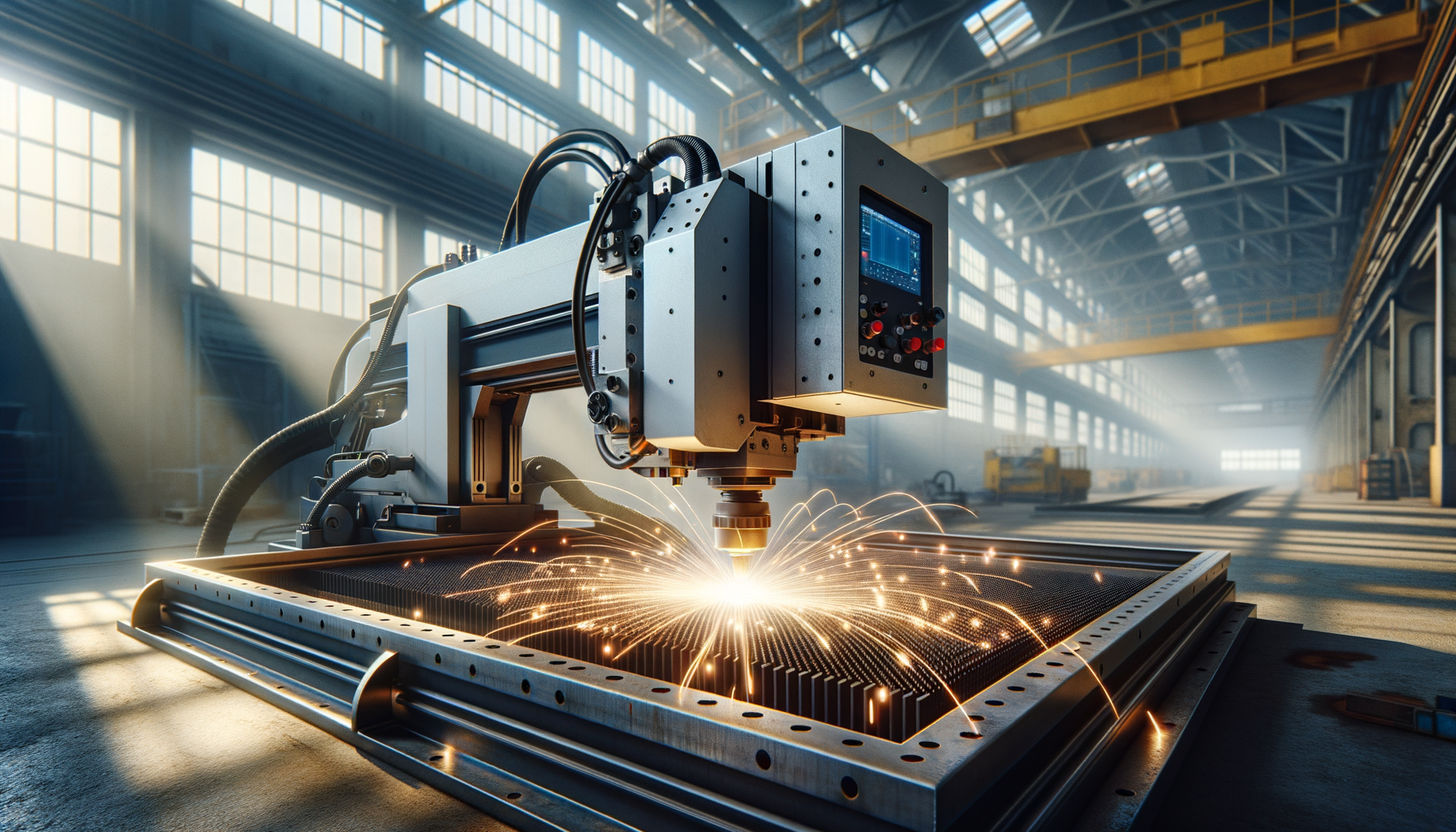

Introduction to Laser Welding Machines

Laser welding machines have become integral tools in several industries, offering precision and efficiency in joining materials. These machines use a laser beam to melt and fuse materials, providing a cleaner and more controlled welding process compared to traditional methods. The demand for laser welding machines has surged due to their versatility, being utilized in sectors ranging from automotive to jewelry making. As industries continue to innovate, understanding the nuances of laser welding machines can help businesses make informed decisions, particularly when seeking affordable options without sacrificing quality.

Key Features of Laser Welding Machines

When exploring laser welding machines, it’s crucial to consider their key features to ensure they meet your specific needs. These machines typically boast high precision, allowing for intricate welds that are essential in industries like electronics and medical device manufacturing. Additionally, they offer a non-contact process, which minimizes the risk of contamination and damage to delicate components.

Laser welding machines are also renowned for their speed and efficiency. They can complete welds in a fraction of the time it takes using conventional methods, which is a significant advantage in high-volume production settings. Furthermore, they provide flexibility in terms of material compatibility, capable of welding metals, plastics, and other materials with ease.

- High precision for intricate welds

- Non-contact process to prevent contamination

- Speed and efficiency in high-volume production

- Compatibility with various materials

Understanding these features can help businesses select a laser welding machine that aligns with their operational requirements and budget constraints.

Industries Benefiting from Laser Welding Technology

Laser welding machines are pivotal in numerous industries due to their adaptability and precision. In the automotive sector, they are used for welding components such as gear parts and exhaust systems, ensuring durability and performance. The aerospace industry relies on laser welding for fabricating lightweight yet robust components, which are critical for safety and efficiency.

In the medical field, laser welding machines are instrumental in manufacturing devices that require precision and sterility, such as surgical instruments and implants. Additionally, the jewelry industry benefits from laser welding technology, which allows for delicate repairs and intricate designs that would be challenging with traditional welding methods.

These machines not only enhance product quality but also streamline production processes, making them invaluable across different sectors.

- Automotive: Gear and exhaust systems

- Aerospace: Lightweight and robust components

- Medical: Precision devices and implants

- Jewelry: Delicate repairs and intricate designs

Factors to Consider When Choosing an Affordable Laser Welding Machine

Choosing the right laser welding machine involves evaluating several factors to ensure it meets both budgetary and operational needs. One of the primary considerations is the machine’s power output, which should align with the materials and thicknesses you intend to weld. It’s also essential to assess the machine’s compatibility with your production environment, including space constraints and integration with existing systems.

Another critical factor is the machine’s user interface and ease of operation. A machine that is intuitive and easy to use can significantly reduce training time and increase productivity. Additionally, consider the cost of maintenance and availability of replacement parts, as these can impact long-term operational costs.

- Power output suitable for intended materials

- Compatibility with production environment

- User-friendly interface

- Maintenance costs and parts availability

By weighing these factors, businesses can invest in a laser welding machine that offers exceptional value without compromising on quality and performance.

Conclusion: Investing in the Right Laser Welding Machine

As industries continue to evolve, the demand for efficient and precise welding solutions remains a constant. Laser welding machines provide an excellent solution across various sectors, offering precision, speed, and versatility. When seeking an affordable machine, it’s essential to consider factors like power output, compatibility, and user interface to ensure it aligns with your operational needs.

Investing in a quality laser welding machine can enhance production capabilities and product quality, providing a significant return on investment. By understanding the key features and benefits of these machines, businesses can make informed decisions that support their growth and innovation.