Understanding Laser Welding Technology in Modern Manufacturing

Introduction to Laser Welding Technology

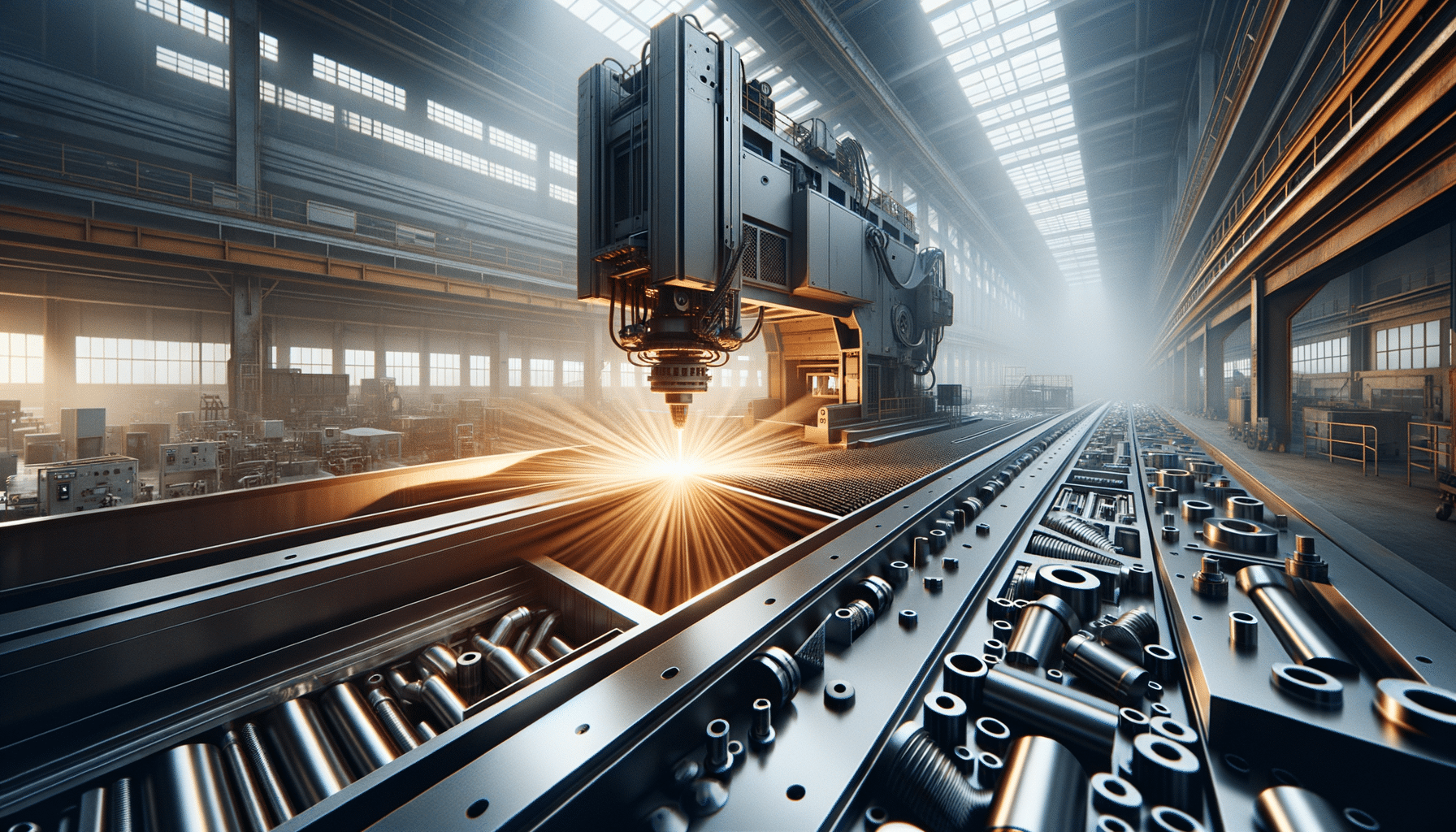

In the realm of industrial manufacturing, precision and efficiency are paramount. Laser welding technology, a method that employs focused laser beams to join materials, has emerged as a noteworthy advancement. This technique stands out due to its ability to deliver high precision and speed, making it a preferred choice in several industries, including automotive, electronics, and aerospace. The process involves directing a concentrated laser beam at the materials to be joined, which melts and fuses them together. This method not only ensures minimal distortion but also allows for complex and intricate welding tasks that traditional methods may struggle with.

The significance of laser welding technology cannot be overstated. It has revolutionized manufacturing processes by offering unparalleled accuracy and control. As industries continue to push the boundaries of innovation, the role of laser welding becomes increasingly critical. Its ability to cater to the demands of modern manufacturing makes it an indispensable tool in the toolkit of engineers and manufacturers alike.

Advantages in the Automotive Industry

The automotive industry, characterized by its demand for precision and durability, has greatly benefited from laser welding technology. One of the primary advantages is its ability to produce high-quality welds with minimal thermal distortion. This is particularly important in automotive manufacturing, where the integrity of the weld impacts the overall safety and performance of the vehicle. Laser welding allows for the joining of dissimilar materials, a common requirement in modern vehicle designs that aim to reduce weight while maintaining strength.

Additionally, laser welding offers significant time savings. The speed at which it operates enables manufacturers to streamline production processes, reducing the time required to assemble components. This not only enhances productivity but also lowers manufacturing costs. Furthermore, the precision of laser welding ensures consistent quality, reducing the need for rework and quality control interventions.

In the context of electric vehicles, where battery technology plays a crucial role, laser welding provides a reliable solution for assembling battery packs. The ability to create strong, precise welds without damaging sensitive components is vital in ensuring the efficiency and longevity of electric vehicles.

Impact on the Electronics Industry

In the electronics industry, where miniaturization and precision are key, laser welding technology offers distinct advantages. The ability to produce small, precise welds without affecting nearby components is invaluable. This is particularly relevant in the assembly of electronic circuits and components, where even minor inaccuracies can lead to significant functional issues.

Laser welding’s precision also allows for the joining of delicate materials, such as thin wires and fragile components, without causing damage. This capability is essential in the production of high-tech electronics, where the margin for error is minimal. The non-contact nature of laser welding reduces the risk of contamination and damage, ensuring the integrity of electronic assemblies.

Moreover, laser welding technology supports the trend towards automation in the electronics industry. Its integration with automated systems allows for continuous production with minimal human intervention, enhancing efficiency and reducing labor costs. As electronic devices become more sophisticated, the role of laser welding in their manufacture will continue to grow.

Advancements in the Aerospace Sector

The aerospace industry, known for its stringent standards and complex requirements, has embraced laser welding technology for its numerous benefits. The ability to produce lightweight yet strong components is crucial in aerospace applications, where weight reduction can lead to significant performance improvements and fuel savings.

Laser welding enables the joining of high-strength alloys and composite materials, which are commonly used in aerospace manufacturing. The precision and control offered by laser welding ensure that these materials are joined without compromising their structural integrity. This is particularly important in the production of critical components such as turbine blades and structural frames.

Furthermore, the aerospace industry benefits from the reduced heat input of laser welding, which minimizes thermal distortion and residual stresses. This leads to improved dimensional accuracy and reduced post-weld processing, saving both time and resources. As aerospace designs become more advanced, the reliance on laser welding technology will likely increase.

Conclusion: The Future of Laser Welding Technology

As industries continue to evolve, the demand for advanced manufacturing technologies like laser welding will only grow. Its ability to deliver precise, efficient, and reliable welds makes it an invaluable tool in modern manufacturing. Across automotive, electronics, and aerospace sectors, laser welding has demonstrated its capacity to enhance production processes and product quality.

The future of laser welding technology looks promising, with ongoing research and development aimed at expanding its capabilities and applications. As manufacturers seek to improve efficiency and reduce costs, laser welding will play a pivotal role in achieving these objectives. By continuing to innovate and adapt, laser welding technology will remain at the forefront of industrial advancements, shaping the future of manufacturing for years to come.